Several misconceptions in the design of large-scale sprinkler irrigation systems

Customers often say that due to the initial unreasonable design of the sprinkler system, the equipment is not easy to use or the operating cost is high. If they want to modify the equipment on the original design, it will cost a lot of money. Today, I will outline several common misconceptions in designing large-scale sprinkler irrigation systems.

1、 No design tailored to local conditions

In the Central Plains region, the vast majority of land parcels are long strips, but many designs still use circular sprinkler irrigation systems, resulting in low coverage (circular irrigation systems only have a coverage rate of about 78%), and other irrigation equipment is needed to cover the corners, increasing management costs. The main reason is that there are many factors to consider when designing a translation machine, while the design of a circular machine is relatively simple. The design of sprinkler irrigation systems must be based on the local terrain and tailored to local conditions. For long strips, a translation machine should be designed, and for square blocks, a pointer machine should be selected.

2、 The design is unreasonable

In North America and Australia, the vast majority of sprinkler irrigation machines are equipped with specialized sprinkler net filters to filter out sediment and impurities in water, reducing the risk of equipment blockage and nozzle wear. At the same time, a check valve is designed at the head to prevent the backflow of pesticide solution during fertilization or spraying, reducing the risk of groundwater pollution. There are also exhaust valves, water meters, etc., which are not considered in the majority of sprinkler head designs.

3、 Unreasonable nozzle selection

The editor found that the majority of sprinkler irrigation machines, especially those tendered for government projects, use refracted nozzles. Although these nozzles are low in price, they have high sprinkler intensity, small spraying radius, and are prone to surface runoff when operating in areas with sticky soil, which can affect the normal operation of equipment. The currently popular nozzle in the international market is the rotary nozzle, which has a high cost but a large spraying radius, low irrigation intensity, and high uniformity. Examples include the Austrian Komet KPT series, the American Senninger I-wob series, and the American Nielsen O3000 series.

We have also found a common problem where different crops are planted with the same type of sprinkler head, without considering the resistance of the crop leaves to impact. For example, when planting corn, cotton, alfalfa, and potatoes, different sprinkler trays are always used, but in the actual design process, crop factors are directly ignored, and the vast majority of planting friends do not care about this matter.

At the same time, in the northwest plateau region, due to the high evaporation rate, the loss of water droplets during spraying and falling is significant. Many designers have not found a solution, such as using LEPA or Bubble nozzles, nor have they chosen nozzles with wind resistance. This point will not be further elaborated in this article.

On pressure regulators, the vast majority of designers still choose 15PSI, mainly due to the use of refractive nozzles. In fact, in foreign countries, most of the pressure bars use 10PSI and are equipped with a rotating nozzle, which can reduce the inlet pressure by 5PSI.

4、 Unreasonable selection of pipe diameter

The four commonly used pipe diameters for sprinkler irrigation machines are 127mm (5 inches), 168mm (6 5/8 inches), There are four types: 219mm (8 5/8 inches) and 254mm (10 inches). Of course, different manufacturers have different parameters, but they are generally similar. The vast majority of sprinkler irrigation machines in China use 168mm, commonly known as 6-inch pipes. However, the selection of pipe diameter must be based on the irrigation area and inlet pressure. For example, for equipment with less than 4 spans, a 5-inch pipe can fully meet the requirements, while for equipment with more than 8 spans, an 8-inch pipe needs to be configured in the first few spans and a 6-inch pipe needs to be configured in the last few spans to reduce pipeline friction loss, thereby reducing inlet pressure and saving energy consumption. In practice, the commonly designed tube is a 6-inch tube.

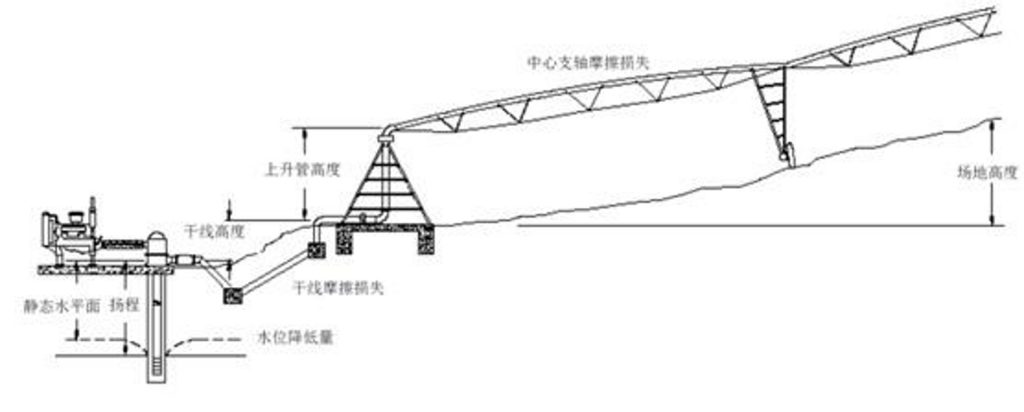

5、 Unreasonable calculation of entry pressure

This is a very common problem, which is caused by incomplete consideration of factors or inaccurate calculations during design. There are many factors that affect the size of the inlet pressure, such as the size of the pressure regulator selected, the actual terrain undulations, the diameter of the sprinkler pipe, etc. Some sprinkler machines even do not have a water pressure gauge. This has led to some sprinkler irrigation machines having excessive inlet pressure and wasting energy consumption; Some inlet pressures are too low to meet the pressure required for the normal operation of the last nozzle pressure regulator.

6、 No anti-skid measures in place

If the sprinkler operates in clay, it may slip. In addition to using a rotating nozzle to reduce surface runoff as mentioned earlier, there are other measures such as rear mounted nozzles, half mounted nozzles, remote drainage, etc. At the same time, suitable tires such as wide tires 16.9-24 should be selected.

Taking tires as an example, almost all sprinkler irrigation machines in China use 14.9-24 tires. As for tires, there are also different numbers of tread patterns, and the more pairs there are, the better the anti-skid effect, making it less likely to slip in muddy ground. From the perspective of herringbone patterns alone, there is also a saying of width. A wider pattern is better for slip resistance, while a narrower pattern is the opposite. In terms of depth, the deeper the pattern, the better the slip resistance, while the shallower it is, the opposite is true.

7、 High speed motors are ignored

The vast majority of sprinkler irrigation machines in China are not equipped with high-speed motors, but when using sprinkler irrigation machines for fertilization, high-speed motors are needed to increase the walking speed of the equipment. At the same time, if you want the equipment to idle for a week before each planting season or temporarily make way for the equipment, high-speed motors can double the speed.

In the design of a translation machine, a high-speed motor is a necessary configuration. Low speed motors are required at both ends of the equipment, while high-speed motors are required for the remaining middle span. In this way, the middle crossbody can catch up with the two crossbodies running first at a higher speed. This is the most fundamental principle.

Due to many of the above issues not being taken into account during the design process, it is inevitable that the nozzle configuration table of the equipment will be incorrect, which will affect the uniformity of irrigation and waste water and fertilizer.