Effective irrigation is one of the most important factors in crop production. Irrigation uniformity refers to the degree of uniformity of water distribution within the irrigated area and is an important indicator for measuring irrigation quality. Uneven irrigation can lead to uneven crop growth, reduce crop yield and quality, and cause surface runoff, resulting in waste of water resources and soil fertilizers, exacerbating soil pollution. There are many factors that affect irrigation uniformity, including wind direction, wind speed, sprinkler tray structure, nozzle size, nozzle adjustment pressure, nozzle spacing, spray height, terrain, and other conditions.

In terms of the current use of sprinkler irrigation machines in China, irrigation uniformity is the most easily overlooked issue. However, with the improvement of users’ own quality, how to improve irrigation uniformity has become increasingly important. For example, in the main potato producing areas of northern China such as Inner Mongolia and northern Shaanxi, more and more growers are starting to consider how to improve the irrigation uniformity and degree of the combination of sprinkler irrigation and fertilization, so as to make the potato seeds under the sprinkler irrigation circle more beautiful in shape and consistent in tuber size. For example, it is generally not recommended to use potato chunks weighing less than 50 grams as seed potatoes during spring sowing. Sweet potatoes are small and contain fewer nutrients. After emergence, the mother can provide relatively less nutrients to the plants. In this case, if natural disasters such as drought occur again, it is highly likely that the plants will not receive sufficient nutrient supply, resulting in wilting or death. The plant is short and weak, with low resistance, weak photosynthetic ability, and few tubers, which has a certain impact on its yield. If the irrigation uniformity is high, it will greatly reduce the number of seed potatoes with smaller tubers.

Introduce several common practical methods to improve the uniformity of irrigation with existing sprinkler systems.

1, Raise the installation height of the nozzle

The higher the installation height of the nozzle, the farther it is sprayed, and the overlap of spraying is about high. However, the water loss is relatively large, and the irrigation efficiency will decrease. Especially in the northwest region of China where wind and evaporation are high, the installation height of the nozzle should not be too high. According to foreign experience, in the absence of wind, when the installation height of the nozzle is within the range of 1.5-2.1 meters above the ground, the efficiency can reach 90%. As the wind speed increases, irrigation efficiency will rapidly decrease. Research shows that when the wind speed reaches 6.5-8.6 meters per second, the irrigation efficiency will correspondingly decrease by 17% -30%.

There are three levels of installation height: high-level installation, mid-range installation, low-level installation, and low-energy precision irrigation installation.

When installed at a high position, the nozzle is above the main pipe of the sprinkler system. Early sprinkler systems used this method, which resulted in the highest spray uniformity and evaporation rate.

When installing in the middle position, the nozzle height is about the middle position between the main pipe of the sprinkler and the ground, and at this time, the nozzle is spraying above the canopy.

Low level installation refers to the installation of the nozzle 0.3-0.45 meters above the ground. At this point, the amount of water intercepted by the leaves is small, resulting in minimal evaporation loss. The so-called low-energy precise irrigation requires the installation height of the nozzle to be between 0.2-0.45 meters or the use of a bottom dragging pipe for irrigation. At this point, the water loss is smaller.

2. Increase pipeline outlet, reduce nozzle spacing, and increase nozzle overlap rate

According to different customer needs, there are generally three types of nozzles spacing: 0.75 meters, 1.9 meters, and 2.9 meters. Choosing a smaller nozzle spacing is generally applied to newly installed sprinkler irrigation equipment.

For existing sprinkler irrigation systems, the number of nozzles can be increased by changing the goose shaped pipe to a Y-shaped outlet.

In addition, it is a very simple and effective way to cross and stagger the nozzles to improve irrigation overlap.

3. Flatten the land and reduce the impact of slope on surface runoff

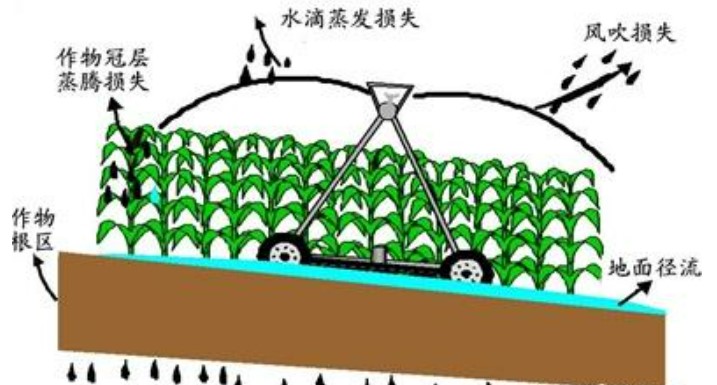

The water loss of the sprinkler is shown in the following figure:

Under slope conditions, in addition to considering the infiltration characteristics of different soils, the impact of slope on surface runoff should also be taken into account. The steeper the slope, the greater the chance of generating surface runoff, resulting in lower water, fertilizer, and production costs. Therefore, growers should try to minimize the slope of the land as much as possible.

4. Select different rotating nozzles according to different crop types

The tolerance of different crops to water droplet impact intensity varies, and the impact intensity of water droplet impact has an impact on soil infiltration, which is a factor that needs to be carefully considered. If water droplets have a small impact on the soil, it is easy to keep the soil capillaries open and maintain a high soil water absorption rate. Small water droplets are beneficial for soil infiltration.

The suitable atomization indicators for different crops vary, as shown in the table below:

Types of atomization indicators

Vegetable and flower: 4000~5000

Grain crops, cash crops, and fruit trees: 3000~4000

Grass, feed crops, lawns 2000-3000

Many customers still use low-quality nozzles or ordinary scattering nozzles, and many nozzle regulators cannot truly regulate the pressure, which can be imagined. The nozzle is usually designed to operate within a large range of pressure changes, which requires maintaining normal working pressure at the nozzle inlet. If the working pressure of the nozzle is too high, it will cause excessive atomization. If the atomization is too high, it will cause a decrease in the spray radius and reduce the uniformity of spraying, resulting in water accumulation or inadequate spraying, and also causing water waste.

We recommend the KOMET KPT nozzle and pressure regulator imported from Austria. Under the same pressure regulation, its unique swirl system and sprinkler design fully ensure that each droplet particle shape, size, and pressure are consistent. Through scientific calculation of the nozzle configuration table, the height uniformity of the nozzle water output is guaranteed. The special molecular material with high strength and ultraviolet resistance can be applied to various lighting environments, and has a strong anti-aging effect. At the same time, one nozzle is equipped with two nozzles, which can be quickly adjusted through ergonomic design to meet the water demand during different crop growth periods.

5. Choose sprinkler trays with different wind resistance performance

Even for the same nozzle, different sprinkler trays will be configured to meet different wind resistance performance. The following picture shows the sprinkler tray of the Austrian KOMET nozzle adapted to different wind conditions.

6. Verify if your nozzle configuration is scientific

Professional sprinkler manufacturers will design a professional sprinkler configuration table for you based on the actual water inlet volume, inlet pressure, sprinkler length, sprinkler diameter, nozzle type, nozzle height, nozzle spacing, and other factors. However, in practical applications, some manufacturers may arbitrarily configure due to weak professionalism and sense of responsibility. In this case, the configuration table cannot guarantee irrigation uniformity. Due to the relatively complex method of calculating irrigation uniformity, many farmers are not very concerned about it, and the problems caused can be imagined.